Can adulterated and/or weaponized bio-chemical substances be definitively excluded from mRNA injections currently marketed as “Covid 19-Vaccines”?

In politics, diplomacy, and export control, “dual-use” refers to technology that can be used for both peaceful and military aims. mRNA technology, including embodiments as injectable drugs or vaccine products, has been long identified as a dual-use technology. See references here, here and here. The “dual-use dilemma” was first noted with the discovery of the process for synthesizing and mass-producing ammonia which revolutionized agriculture with modern fertilizers but also led to the creation of chemical weapons during World War I. The dilemma has long been known in chemistry and physics, and has led to international conventions and treaties, including the Chemical Weapons Convention and the Treaty on the Non-Proliferation of Nuclear Weapons.

In 1997 the JASON group, identified potential genetically engineered pathogens in the following six groups:

· Binary biological weapons

· Designer genes

· Gene therapy as a weapon

· Stealth viruses

· Host swapping diseases

· Designer diseases

To date, both awareness and control systems for detection and elimination of the potential for subversion and misuse remain woefully inadequate. Despite obvious threat introduced by advanced synthetic biology products, if misused as weapons, little to no control measures exist today beyond a handful of guidance documents[6] for scientists and research institutions (which are largely ignored, and/or such research offshored to numerous contractors).

As I discuss further in this article, the mRNA/DNA products as manufactured and distributed today, are poorly controlled, and significantly open to adulteration whether intentional or as a result of product degradation and lack of proper process controls and purity characterization. Technical capabilities that are required to reliably characterize and control these substances at the point of manufacture, in distribution, and administration are not routinely established, neither by the manufacturers nor by the regulators worldwide.

Gene Therapy as a Weapon:

When gene therapy is used as a weapon, in addition to protein-encoding genes, genes that encode RNA products such as short hairpin RNAs (shRNAs) or micro RNAs (miRNAs) could potentially be exploited as weapons in their own right.

The following paragraph is found in Chapter 6 of the 2018 edition of the textbook “Biodefense in the Age of Synthetic Biology”:

“Small RNAs are an example of functional genetic information that could be horizontally transferred. Small RNAs, although not a genome modification per se, are important because they may prove capable of modifying gene expression and bringing about phenotypic change. The large number of small interfering RNA (siRNA), short hairpin RNA (shRNA), micro RNA (miRNA) (Zhang et al., 2007; Huang et al., 2008), and other small-RNA library studies in a variety of species and cells from different species, including human, provides a potential roadmap of what sequences may lead to what disease states or to modulation of defenses against disease. {…}

One reason that RNA delivery is potentially a viable biological threat is that even a small initial skew in gene expression (such as the changes in gene expression normally caused by miRNAs) could greatly alter the probability of an initial cellular alteration. Even small amounts of a targeted RNA would not modify the genome per se, but might allow or encourage cells to begin the process of self-transformation to tumors, as evidenced by the fact that a large number of pro-oncogenic miRNAs have already been discovered (O’Bryan et al., 2017). In addition to RNAs produced by viruses, bacteria produce numerous small regulatory RNAs; introduction of these into the endogenous microbiome could lead to dysbiosis. Larger mRNAs can also be delivered via liposomes and nanoparticles or by RNA replication strategies being developed for vaccine production (see Chapter 8, Rapid Development of Self-Amplifying mRNA Vaccines); these methods could potentially be used to express deleterious cargo such as toxins or oncogenes, similar to threats related to DNA vectors.”

Clearly, both small and larger RNA sequences can be introduced into the human body for nefarious purposes, including promotion of cancer, dysbiosis, immune system suppression and organ damage. This can be accomplished with and without incorporation of the weaponized RNA code into the host genome and by RNA sequences that do not need to encode any protein.

Technical Capabilities Required for Independent Evaluation and Characterization of mRNA Products:

How would anyone determine that a vial of an injectable substance does not contain potentially weaponizable synthetic biology? The expected answer is that for this reason we have pharmaceutical regulations, and cGMP laws requiring disclosure of ingredients and their purity, traceability, established multi-year rigorous step by step preclinical and clinical trials process where the product is carefully assessed in well designed and controlled studies, and presented to the independent review and audit by the ”competent authorities” (FDA, EMA, MHRA, etc.), GMP compliance is required, and the careful assessment includes extensive requirements to characterize the product’s quality, purity, potency, acceptance criteria and testing for impurities, etc.

However, this is precisely what DID NOT occur with the C-19 injections. There was no careful multi-year process of testing. There was a media-government-manufactured global panic and a mad highly politicized “rush” to put these injections on the market regardless of laws, ethical standards or regulatory objections raised. There were indeed 100+ formal objections raised by EMA reviewers for Pfizer days before market authorization and none of them were resolved before millions of doses were shipped globally. The most critical ones remain unresolved to this day. There were no GMP inspections of the manufacturing facilities in 2020 at all, no GMP compliance prior to shipping millions of doses worldwide, and currently hundreds of contractors and suppliers remain uninspected, especially those overseas. In addition, numerous clear warnings of lack of safety, evidence of disease enhancement, tremendous harm from side effects, evidence of fraud in clinical trials reported to the FDA by whistleblowers, evidence of sloppy, uncontrolled and very likely fraudulent manufacturing appeared virtually from the start of the rollout. All of this was accompanied by gaslighting and denial by the public safety authorities as well as their mass media enablers.

Theoretical Regulatory Requirements for mRNA Manufacturing and Control

This section is titled “Theoretical” as in practice these rules are being largely ignored by the manufacturers and the regulators who are not enforcing them in regard to mRNA/DNA injections. You can find the answer WHY in this video and in this video discussion with Katherine Watt as well as in much more detail on her substack.

mRNA manufacture is a vast and complex technical topic, and I am not able to cover it in a short article. I will focus on one area only – characterization of the active substance mRNA. The product consists of Drug Substance (mRNA) and Drug Product (LNP and other ingredients). There are numerous wide-open areas where the active substance of the product can be augmented or replaced without detection by normal quality control steps, and in some cases – by any methods.

mRNAs are produced by in-vitro transcription using recombinant polymerase, representing the current large-scale manufacturing technology. Let’s remember, that we are discussing a “modified” RNA, i.e. a nucleic sequence that does not occur in nature, and has undergone many synthetic modifications, proprietary to the manufacturer. I consulted several sources, here on the state of the art of the manufacturing quality control and regulatory requirements for characterization of the mRNA products as medicines.

The basis for the correctness of the mRNA structure is the identity of the plasmid DNA template, which is verified by fully automated DNA sequencing, which must be GMP-certified. This template is a starting point for making RNA, just like a film negative from which a photo print needs to be made. These DNA templates are ordered from various suppliers, who have traditionally supplied tiny quantities for scientific research needs that almost never require GMP quality. Today, the availability of GMP grade plasmid DNA has become an industry bottleneck. Few suppliers are providing any GMP certification, and even when they do, the material they deliver is certified only to about 30% fidelity, often not even that high. Meaning 70% can contribute to the in-process DNA impurities. Manufacturing mRNA and DNA vaccines requires significant quantities of DNA, which is used directly as the product in a DNA vaccine, or as a starting template for an enzymatic reaction for mRNA production. As an example, delivering one billion doses of an mRNA vaccine may require production of in excess of 1 kg of DNA! I can assure everyone that the majority of this was non-GMP compliant research grade material, if it was indeed delivered in this volume at all (I have doubts about feasibility of this).

As a side note – plasmid DNA template manufacturing necessitates insertion of antibiotic resistance genes into the starting DNA template which is grown in e-coli cells that are subsequently killed off by antibiotics to “harvest” the DNA template. These genetic materials end up in all biological products being manufactured. Since now these are being pushed onto the world in KILOGRAMS – what is the implication to antibiotic resistant bacteria springing up all over the planet? Next question, if e-coli become antibiotic resistant due to cross-contamination, and are not killed entirely in the harvesting process, how much of them end up in the injection vials? Endotoxins are a known severe problem in vaccine manufacturing.

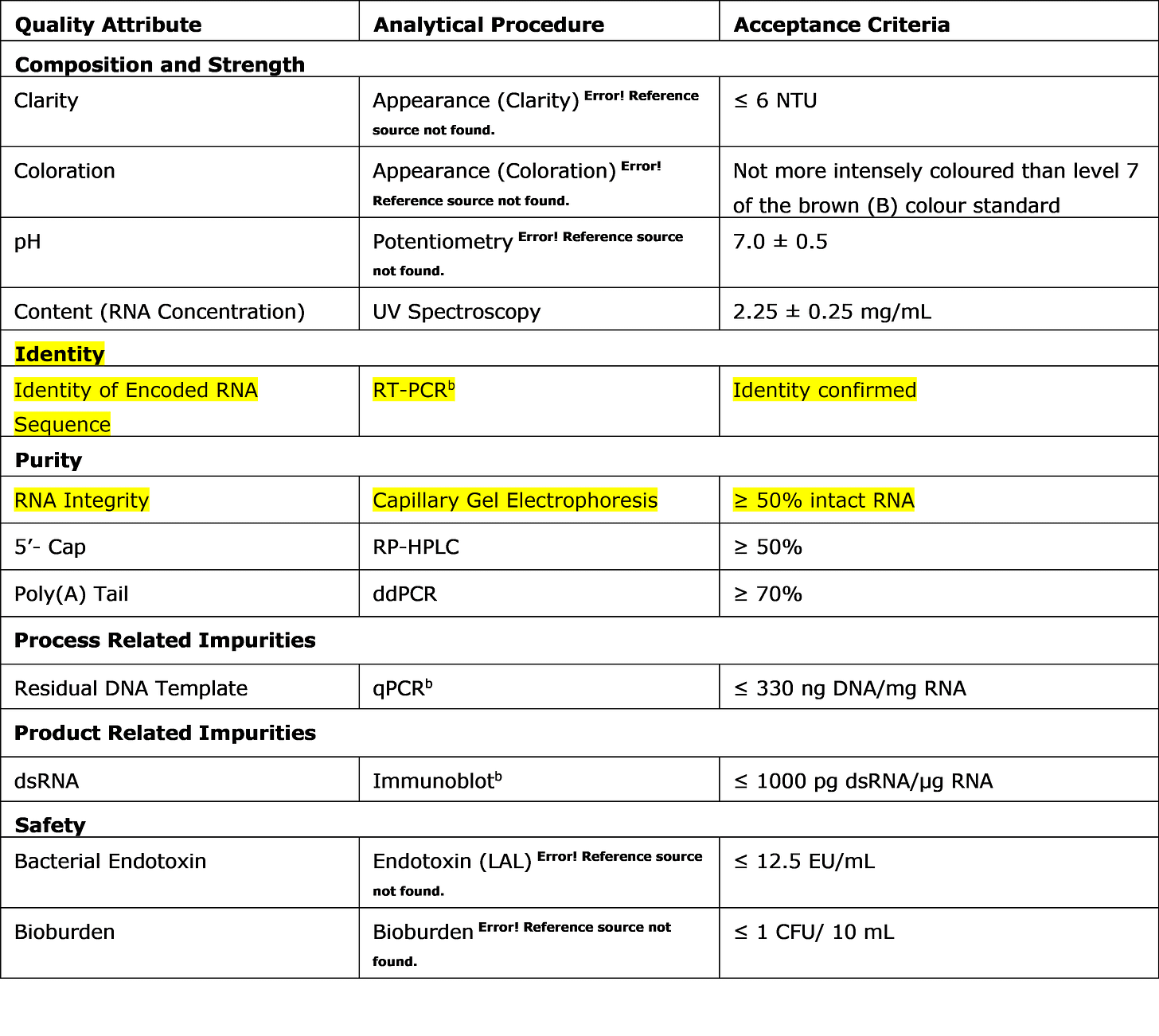

A regulatory-required chapter in any new drug application dossier is “Control of the Drug Substance”. This chapter is part of the Chemistry Manufacturing Controls (CMC) section of the dossier, which is Module 3 in the FDA BLA application. It demands a specification of the drug substance, giving information on analytical procedures and their acceptance criteria, addressing mRNA identity, assay and impurities. One of the key elements guaranteeing the quality of the drug substance is a product specification based on the current state of product development as well as science and technology. For this, the framework is set by International Conference on Harmonization (ICH) guideline Q6A “Test procedures and acceptance criteria for new drug substances and new drug products: chemical substances”. The specification defines a list of tests along with references to analytical procedures and appropriate acceptance criteria for the quality assessment of the respective product regarding identity, assay/quantity, purity/impurities, and potency/ biological activity.

All analytical procedures must be fully validated, which means that either standard, previously validated methods are used, or if proprietary or novel – then the manufacturer must invent and fully validate the assays that are used for novel techniques. This requires, among other things, definitive tests with positive and negative controls as well as full and traceable documentation “audit trail” for every test. Commercial secrecy is not an excuse. Even if the manufacturer does not wish to publicly disclose their analytical procedures, they still must submit full transparent documentation to the FDA who holds it on file (and this fact is formally communicated to purchasers of the product for their own GxP compliance).

Pfizer’s Description of Analytical Tests Used to Characterize the Active Substance of the mRNA Injections:

In Pfizer’s CMC documentation leaked at the end of 2020, thereviewersfrom EMA noted that there was no description of the “non-compendial”, i.e. Pfizer’s own methods for analytical procedures. The EMA reviewers wrote: “The proposed commercial drug substance specifications, the method descriptions and the method validation summaries should be updated to include in-house method identification numbers for the non-compendial methods. The information is required in order to provide a clear link between the specification and the descriptions and validations of analytical procedures used for routine testing. Furthermore, for the compendial methods references to relevant parts of the Ph Eur should be included. Section 3.2.S.4.1, 3.2.S.4.2 and 3.2.S.4.3 of the dossier should be updated accordingly”.

a. Compendial

b. Assay not performed on stability.

Abbreviations: NTU = Nephelometric Turbidity Units; B = brown; RT-PCR = reverse transcription polymerase chain reaction; ddPCR = droplet digital PCR; qPCR = quantitative PCR; dsRNA = double stranded RNA;

LAL = Limulus amebocyte lysate; EU = endotoxin unit; CFU = colony forming unit

The test used for mRNA identity testing is RT-PCR (real-time PCR), described by Pfizer as follows:

“Reverse Transcription-Polymerase Chain Reaction (RT-PCR)

The purpose of this analytical procedure is to confirm the identity of the encoded RNA sequence derived from the BNT162b2 (pST4-1525) products. This procedure uses primers and a probe specific for the pST4-1525 sequence to perform a single step real-time RT-PCR assay intended for the detection of nucleic acid from RNA in both drug substance (DS) and formulated RNA lipid nanoparticle drug product (DP). Identification of the RNA is reported as presence or absence of the target RNA.

A single step RT-PCR assay is performed to detect nucleic acid from the RNA in DS and formulated DP. This assay is designed to detect a target of 63 bp amplicon in a gene that encodes for S protein in the BNT162b2. The amplicons are detected using a real-time PCR system that measures the fluorescence signal generated during amplification in real-time.”

The mRNA is a highly unstable and fragile substance, which, while manipulated and “optimized” for stability, still has shown a great degree of fragility. Cryogenic freezing does not seem to solve this problem fully. As a result, the integrity of the mRNA has been problematic, especially with the scale up of manufacturing, and as shown above the acceptance criterium for the %mRNA integrity was arbitrarily set at just greater than 50%. That means that a large portion of drug substance contains “junk” RNA material, fragments, and uncharacterized pieces, some of them large enough to code for unknown and possibly aberrant proteins, and most of them falling into the category of micro RNAs (miRNAs). These short sequences, while non-coding, are known to interfere with genetic cellular processes and thus are implicated in cancer pathways. As noted at the beginning of my article, miRNA have been long designated as a type of biological weapon technology. In this context, it is quite shocking that no analytical tests or procedures are being conducted by the manufacturer and no information of what types of RNAs are likely to result from the degradation of mRNA in manufacturing process or in the vials, or due to handling at the administration site, neither their impact on safety nor efficacy of the product has ever been addressed.

The regulators raised many concerns about suitability of the analytical tests and the details provided by Pfizer on validation of their in-house assays. In the quote below, “OC” is a major regulatory observation/flag that normally must be addressed fully prior to product authorization and commercial shipping. “DS” = drug substance (mRNA), “DP” = drug product, mRNA encapsulated in LNP and other ingredients. Emphasis added by me:

“A general comment which applies to several/all the analytical method descriptions in this section is that rather brief details are given. Some of the assays are not presented in sufficient detail and often method descriptions are based on “examples” of procedures, controls and standards as well as on “typical” system operating parameters (OC). This hampers a full understanding the operation or, sometimes, the scientific basis of the assay. Furthermore, since several of these assays are none standard and complex, this interferes with assessment of suitability. The lack of sufficient information on critical reagents, standards or equipment hinders regulatory control of critical aspects of the assays. Several concerns are raised for specific assays requesting that critical procedures, reagents, standards and equipment are highlighted (see below).

· For all in-house analytical procedures used in the release of DS, method descriptions are based on “examples” of procedures, controls and standards as well as on “typical” system operating parameters. These terms raise uncertainties regarding the developmental stage, and the control of critical steps of these assays. The analytical methods used in the control of DS are expected to be finalized. The applicant is requested to confirm this and to update the relevant parts of the dossier with unequivocal method descriptions and additional details, if needed. The applicant should also confirm that any significant changes in analytical procedures will be applied for in a variation procedure. The dossier should be updated accordingly.

S.4.3:

It is claimed that the analytical methods were validated against the parameters presented in ICH Q2(R1). However, the validation summaries presented are far too brief to be able to conclude on suitability of the in-house analytical methods. The quality of BNT162b cannot be properly assessed, if the reliability of the analytical methods cannot be guaranteed.

· The information in the dossier does not support that any of the in-house analytical procedures applied for drug substance has been properly validated in line with ICH Q2. The validation summaries provided are far too brief and important details are missing. The Applicant should submit more comprehensive validation summaries of all non-compendial methods, for example in the form of short validation reports. The validation summaries should include all relevant calculations, acceptance criteria, description of and results obtained for individual samples. Chromatograms and dose response curves should be included, where applicable.

Module 3.2.S.4.3 of the dossier should be updated accordingly.

CGE and RP-HPLC

The in-house analytical methods for CGE and RP-HPLC are at large well described and includes details on typical test conditions, operating parameters, representative electropherograms and chromatograms as well as information on system suitability testing. However, as further detailed in the general question above use of wording “an example sample preparation” and “typical operating parameters” is not found appropriate”.

Reverse Transcription-Polymerase Chain Reaction (RT-PCR)

The RT-PCR method is used to determine the presence of the encoded RNA sequence derived from the pST4-1525 and, in general, is deemed suitable to estimate identity of BNT162b2 products. Three replicates per sample are used and positive and negative (nuclease-free water and lysis buffer included in the extraction process for DP control) controls are included. The method description, however, does not include information on the nature of the positive control. Furthermore, the method description is based on “examples” of control solution preparations and method procedure as well as on “typical” system operating parameters. A clear and unequivocal description of the method should be provided. Furthermore, a description of the mRNA extraction step needed for determination of the identity of BNT162b2 DP should be included and this step should be appropriately addressed in the method validation procedures (OC).

The proposed assay acceptance criteria for the qualitative RT-PCR-based assay used for determination of DS identity requires a Ct value for the positive PCR control of NMT than 32 simultaneous with a Ct value for the negative controls of NLT 32. The applicant is requested to further justify the suitability of this method in relation to these acceptance criteria, especially in the absence of validation data (OC).

The mRNA extraction step needed for determination of the identity of BNT162b2 DP should be included in the description of the RT-PCR-based assay and this step should be appropriately addressed in the method validation procedure (OC).

The RT-PCR method has been validated with respect to specificity and robustness (dilution of DS and mRNA extracted from DP, amplification extension time and extraction protocols) but only short summary in tabular format has been provided, which is not considered sufficient for a proper evaluation (OC).

· Regarding the RT-PCR method for determination of DS and DP identity:

a) Information regarding the positive control used in the should be provided.

b) The proposed assay acceptance criteria for the qualitative RT-PCR-based assay used for determination of DS identity requires a Ct value for the positive PCR control of NMT than 32 simultaneous with a Ct value for the negative controls of NLT 32. These criteria are not considered relevant to support method suitability. More stringent acceptance criteria should be established and supported by relevant data.

c) The mRNA extraction step needed for determination of the identity of BNT162b2 DP should be included in the description of the RT-PCR-based assay and this step should be appropriately described and addressed in the method validation procedure. This question relates to the DP part of the dossier.”

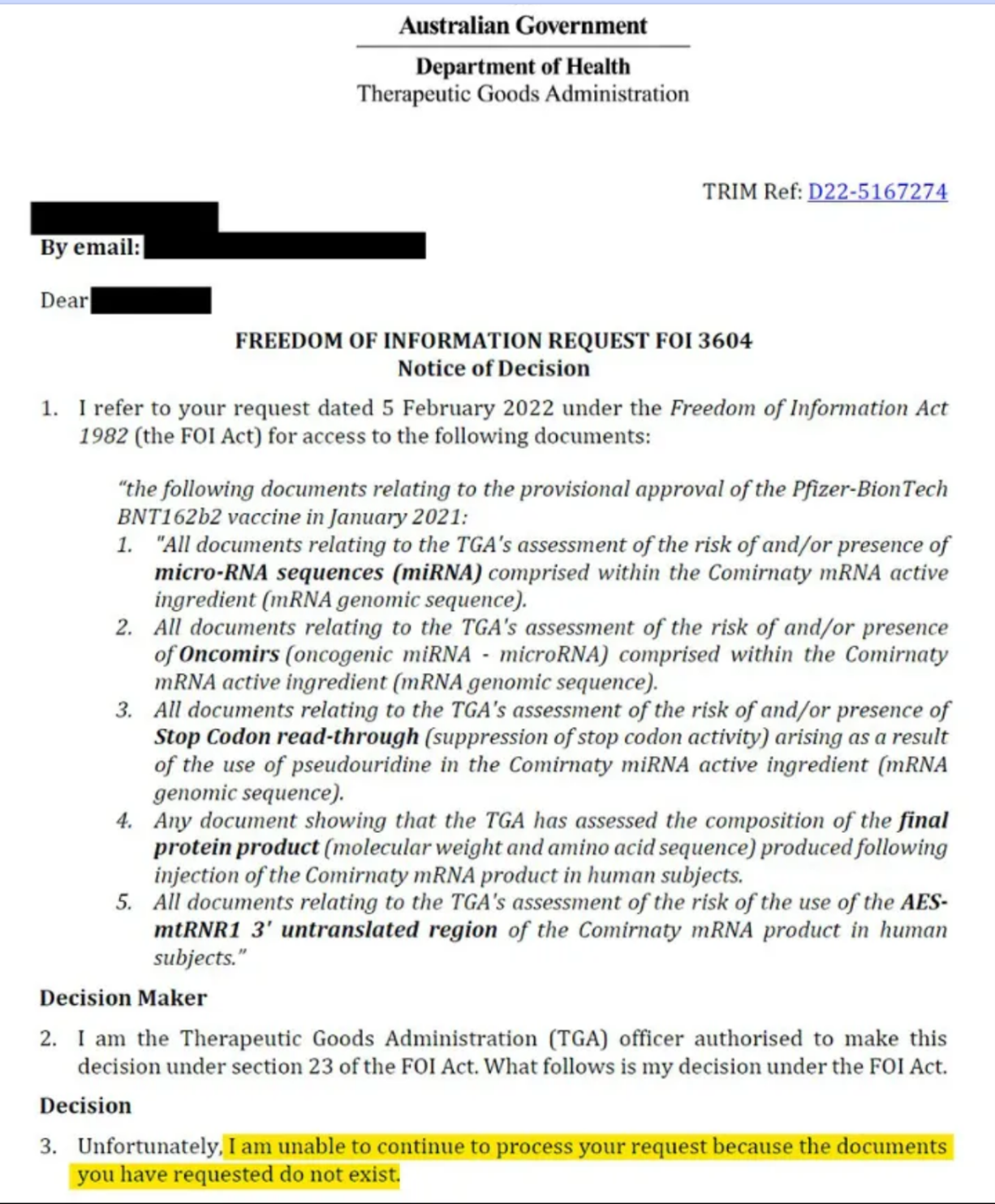

The regulators DO NOT know what miRNAs and other impurities are in the vials.

The concerns of the EMA regulators, and 100+ noted and flagged deficiencies in Pfizer’s CMC dossier have never been addressed, to the best of my knowledge. The manufacturers and regulators both claim commercial secrecy, however it is evident that on many critical issues the regulators are either kept in the dark or prefer if it looks this way. Since the regulators have full authority of enforcement, they are not just helpless victims of big bad pharma companies that want to keep secrets – they are fully complicit enablers or worse, they are driving the subversion of the law. An attempt to find whether a drug regulatory agency knew the answer to this question in relation to Covid-19 mRNA injections produced a “we don’t know” answer from Australia’s TGA (the FOIA request was posted online by Dr. Jessica Rose):

Australia’s TGA is not unique in their lack of capabilities or data to answer these questions. I am willing to bet that for mRNA or DNA vector products, none of the world’s pharmaceutical regulators have the required technical capabilities, laboratory assets, validated assays and expertise to evaluate independently from the manufacturer whether a nefarious biowarfare agent is being sold in their country under the guise of medicinal product. I am making this statement with confidence since it is clear from the regulatory documentation that the manufacturers themselves do not have the necessary analytical methods to test their own products. So-called “competent authorities” are woefully incompetent when it comes to these types of synthetic biology substances.

Therefore, the weaponization of mRNA/DNA technology cannot be excluded, reliable methods to test for product purity and conformity do not exist, and neither regulators nor manufacturers are transparent about the true contents of these products.

Source – https://sashalatypova.substack.com/p/mrna-injections-as-a-dual-use-technology